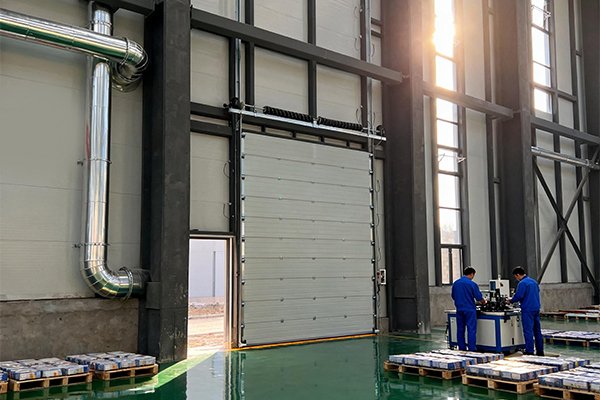

Industrial sectional doors, also known as industrial overhead doors, are high-performance door systems specifically designed for large openings. They typically consist of multiple horizontal panels hinged together, which, through a precise counterbalance system, allow the door to open vertically upwards along the opening and eventually rest horizontally above the doorway. Compared to traditional swing doors or standard rolling doors, industrial sectional doors maximize both interior and exterior space, and due to their robust construction and excellent sealing performance, they have become one of the most widely used door types in industrial settings.

How Do Industrial Sectional Doors Work?

1. Door Panel Structure and Track System

Industrial sectional doors feature panels constructed from double-layer steel plates sandwiching polyurethane foam insulation, offering high strength and excellent thermal and sound insulation. These panels are connected by hinges to form a single unit. Precision track systems are installed on both sides of the door opening. When the door opens, rollers on both sides of the door travel upwards along the tracks. Upon reaching the top, aided by a torsion spring system, the door pivots and slides horizontally along the ceiling.

2. Core Counterbalance System

High-strength torsion springs, precisely calculated and installed above the door opening, are the “heart” of industrial sectional doors. They counterbalance most of the door’s weight. This means that whether operated by a motor or manually, only minimal resistance needs to be overcome, ensuring smooth, effortless, and safe operation while significantly extending the motor’s lifespan.

3. Safety and Protection Systems

Industrial sectional door motors come standard with a safety clutch that automatically reverses when an obstruction is encountered, preventing pinching injuries or equipment damage. Additionally, they are equipped with a torsion spring break safety device, cable break safety device, and end-of-travel buffering. These multiple safety features ensure the security of personnel and goods.

Why Choose an Industrial Sectional Door? Detailed Core Advantages

1. Maximum Space Utilization

When open, industrial sectional doors occupy no floor space, either inside or outside. Unlike swing doors that require significant clearance, they allow vehicles and equipment to be parked and operated right up to the door opening, greatly optimizing space layout and improving operational efficiency.

2. Exceptional Durability and Longevity

Constructed from high-strength, rust-treated materials, industrial door panels can withstand harsh industrial environments. The core torsion spring system is rigorously tested to perform tens of thousands of cycles, ensuring stable operation for years to come.

3. Superior Sealing and Insulation Performance

Seals between door panels and a U-shaped bottom seal effectively prevent the intrusion of wind, sand, rain, dust, and insects. Panels filled with high-density polyurethane foam provide excellent thermal insulation, helping to maintain a consistent internal workshop temperature and significantly reducing energy costs for heating or cooling.

4. Robust Safety Assurance

From bottom safety edges to torsion spring break protection, cable break safety devices, and end-of-travel buffering, industrial sectional doors offer a multi-layered safety and protection system, effectively safeguarding employees and equipment.

5. Aesthetics and Enhanced Corporate Image

With a clean and modern design, industrial doors can be customized with paint finishes to match the building’s exterior, seamlessly integrating with the architecture and enhancing the company’s overall professional image.

Industrial Sectional Doors vs. High-Speed Roll-Up Doors: How to Choose?

In fact, sectional doors and high-speed doors are not mutually exclusive in some functions; rather, they can complement each other.

Industrial sectional doors are primarily used for main entrances, emphasizing security, insulation, and durability, though their opening speed is relatively slower.

High-speed roll-up doors are used for internal workshop passages, emphasizing frequent, rapid opening (up to 2.6-3.9 feet per second) and isolation (e.g., dust control, temperature regulation).

In many modern factories, it’s common to see robust industrial sectional doors installed at main entrances, while internal clean room passages are equipped with high-speed roll-up doors, working in synergy.

How to Choose Your Industrial Door?

An industrial sectional door is far more than just a “door”; it’s an indispensable component of modern industrial buildings, embodying efficiency, safety, and energy management. By thoroughly understanding its working principles and core advantages, we believe you can make the most informed decision, opening a gateway to efficiency and safety for your business operations. If you have any questions or need specific product consultation, please feel free to contact us at SEPPES!