When selecting a industrial sectional door for your warehouse, garage, or industrial facility, you likely know you need a robust and durable option. However, the available space above your door opening is the real determining factor for installation methods and overall performance. Choosing the right lift type not only ensures smooth operation and a long lifespan for your door but also maximizes your valuable space.

Before We Dive In, Let’s Clarify Some Core Concepts:

Headroom Height Above Door Opening: The vertical distance from the top of the door opening to the ceiling or any overhead obstruction.

Door Opening Height: The actual vertical height your door panels cover.

Overhead Space: The area above the door opening where the door panels “travel.”

Generally, Industrial Sectional Door Come in Three Main Installation Types:

1. Standard Installation – Headroom≥20 inches

Installation Conditions: Your door opening has at least 20 inches (500mm) of clear headroom.

How it Works: When opening, the door panels first move vertically upwards for approximately 30% of the door opening’s height. Then, through a curved track, they begin to move horizontally towards the ceiling, eventually resting parallel to the ceiling. The entire travel path forms a smooth “L” shape.

Technical Highlights:

The track system consists of three parts: vertical tracks, curved tracks, and horizontal tracks.

The horizontal tracks require ceiling space roughly equal to the door opening’s width.

Requires moderate torsion spring force, with a relatively standardized balancing system design.

Key Advantages:

Cost-Effective: As a standard solution, it has the lowest material and installation costs.

Good Space Adaptability: Meets the needs of most residential garages and standard industrial door openings.

Mature Technology: Standardized installation process and easy maintenance.

Ideal Applications: Residential garages, small warehouses, retail storefronts, and other locations without significant overhead obstructions above the door opening.

2. High Installation – Headroom > 20 inches

Installation Conditions: The clear headroom above the door opening is greater than 20 inches but less than the full height of the door opening.

How it Works: The operating principle is similar to standard lift, following a “vertical then horizontal” path. However, the key difference is an increased vertical lift section. The door panels move upwards for a greater distance before transitioning to the horizontal. This results in the horizontal section of the door resting higher and closer to the ceiling when fully open.

Technical Highlights:

The vertical track portion of the track system is longer, and the radius of the curved track may also be larger.

Requires more precise calculations to determine the length ratio of the vertical and horizontal sections.

Torsion springs need to provide greater force to balance the longer vertical lift stage.

Key Advantages:

Maximizes Under-Door Clearance: By lifting higher before going horizontal, it creates significant unobstructed space inside the door opening. This allows for parking taller vehicles or stacking higher goods along the wall.

Ideal Applications: Warehouses, repair shops, and garages with tall vehicles where interior space is tight and the door needs to clear the area below when open.

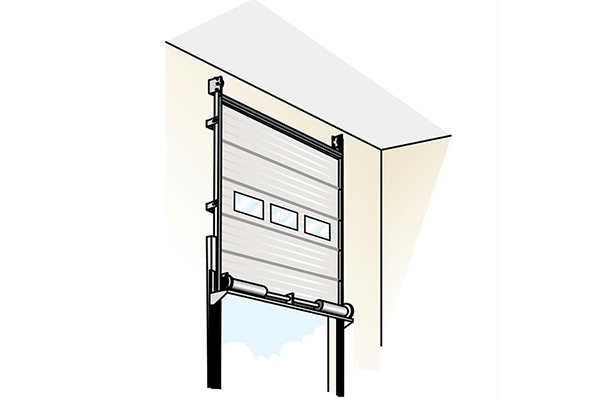

3. Vertical Installation – Headroom≥Door Opening Height

Installation Conditions: The clear headroom above the door opening must be greater than or equal to the door opening’s actual height.

How it Works: When opening, the door travels entirely vertically upwards along the tracks until it is fully parallel to the door opening and tight against the inner wall.

Technical Highlights:

The track system consists only of two vertical tracks extending from the floor to the ceiling height.

Requires robust anchor points on the ceiling or wall structure to support the lifting mechanism and balancing system.

Typically uses more powerful spring assemblies or heavy-duty industrial operators to directly lift the entire weight of the door.

Key Advantages:

Unobstructed Door Opening: When the door is open, the entire door opening area (above and to the sides) is completely clear, providing maximum space utilization. This is crucial for facilities requiring extremely high traffic efficiency or frequent use of large machinery.

Superior Sealing: Due to the simple, direct track structure, there are fewer gaps at curved sections, generally providing better overall sealing performance, which helps with insulation.

Robust Structure: The direct vertical lift method distributes forces more directly, making it more reliable for frequent, high-intensity use.

Ideal Applications: High-standard industrial facilities, logistics transfer centers, and food or pharmaceutical industries with stringent cleanliness or insulation requirements.

How to Choose Your Door

Selecting a industrial sectional door is much more than simply picking a door panel. Clearly define your needs, take accurate measurements, and consult with professionals. As a manufacturer with 14 years of experience in the industrial sector, SEPPES has provided various doors for diverse industries, solving a wide range of challenges. SEPPES strives to consider every potential issue for our clients and offer the most suitable industrial door solutions.