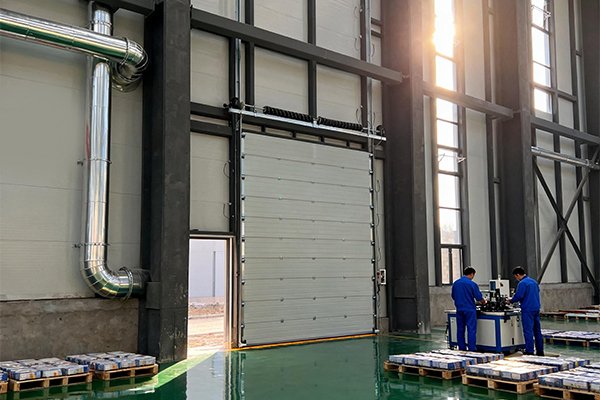

Industrial overhead door is indispensable facilities in warehouses, factories, and logistics centers. Their safety directly impacts the well-being of personnel, equipment, and internal assets. A truly safe overhead door goes beyond robust panels; it’s defined by meticulous attention to detail and proactive anticipation and prevention of potential risks.

Safety Edge: Automatic Reversal Upon Contact

The bottom edge of the door is the most frequent point of passage for personnel and vehicles, making it the highest-risk area. High-quality overhead doors are equipped with a flexible safety edge. Should the door encounter an obstruction (like a vehicle or person) during its closing cycle, this edge swiftly senses it, triggering the door to automatically stop and reverse its direction. This effectively prevents crushing incidents, providing a crucial safety barrier for daily operations.

Torsion Springs and Anti-Breakage Devices: The Core Weight-Bearing System

Torsion springs are typically mounted above the door opening, fixed to a steel shaft. They balance the door’s weight, making operation smoother and easier.

Dacromet Coating Process

Traditional electroplating coatings are prone to rust and corrosion, posing a risk of spring breakage. Torsion springs treated with the Dacromet process offer superior rust and corrosion resistance, effectively withstanding harsh industrial environments like high humidity or exposure to acids and alkalis. This significantly extends spring life, maintains long-term stable support, and reduces the risk of breakage due to corrosion.

Torsion Spring Anti-Breakage Device

This device involves a high-strength steel strap or safety cable installed either inside or outside the torsion spring. In the event of a spring breakage, this mechanism immediately locks the fractured spring, preventing it from recoiling and causing secondary injury to personnel or equipment.

Multiple Anti-Fall Designs: Cables and End Buffers

Cable Anti-Fall Device

This device is installed at both ends of the drum. If the cable unexpectedly loosens or breaks, the anti-fall device instantly activates, preventing the door from falling unintentionally and minimizing risk.

End Buffers

The door needs to stop smoothly and gently when reaching the top or bottom of the track. End buffers, through internal elastic or hydraulic mechanisms, provide cushioning for the door’s movement, achieving smooth deceleration and stopping. This not only eliminates noise and vibration from hard impacts, protecting the door structure, but also ensures stable and reliable operation.

Safety is a Systemic Endeavor

A truly safe industrial overhead door is the result of multiple safety technologies working in concert. From active sensing at the bottom, to corrosion protection and anti-breakage features for the core torsion springs, and finally to cable anti-fall and end buffers – every stage is multi-layered in design. When selecting an overhead door, focusing on these inherent, detailed safety configurations is far more important than merely comparing panel thickness. Together, they build a reliable safety system, providing robust protection for your business continuity and personnel safety. If you’re considering such an overhead door, please contact us at SEPPES for professional door solutions.