The loading and unloading platform effectively bridges the height difference between the truck bed and the platform through the coordinated operation of the control system, electric-hydraulic power unit, adjustment plate, and lip plate, significantly improving operational efficiency. It features a dynamic load capacity of 6.3T and a static load capacity of 13.6T.

Safety is enhanced with automatically retractable side guard baffles, a reliable hydraulic speed control valve, and an anti-fall safety valve. The 400mm innovative double 5° arch-bridge reinforced lip design ensures a smoother transition, minimizing impact damage to forklifts, platforms, and the dock leveler.

For specialized environments, telescopic dock levelers are available, offering a dynamic load of 6,000 kg, static load of 8,000 kg, and a telescopic lip extension of up to 1,000 mm. (Patented technology)

Dock Leveler Introduce

What Are the Advantages of Choosing SEPPES Dock Leveler?

Advanced Lip Design

The integrally reinforced lip is available in 40 cm or 50 cm thickness, offering excellent strength and durability. The non-slip tread plate surface ensures high load capacity and resistance to wear during frequent operations.

Enhanced Load Capacity

With options for 6T, 8T, and 10T capacities, the dock leveler meets diverse industry needs. Rated for 6.3T dynamic and 13.6T static loads, it ensures efficient and reliable cargo handling.

Stronger Load Carrying Capacity

The intelligent control system adjusts height differences between platforms and vehicle beds, ensuring stable support and smooth operation throughout the loading process.

Reliable Safety Protection

Equipped with a hydraulic speed control valve and anti-fall valve, the platform maintains strong, stable support, enhancing operational safety for personnel and equipment.

The Unique Design of the SEPPES Dock Leveler?

Start your own exclusive customization

Lip

Innovative double 5° arch bridge type reinforced tongue plate design technology.

Side Seal

Both sides are equipped with rubber seals to effectively prevent dust intrusion.

Optional dual hydraulic pump

Carrying a large weight, smoother transportation.

Motherboard stiffener

Ensure the platform is supported with enhanced stability and strength.

Six Key Functions Of The Dock Leveler

Optimized for Efficiency, Safety, and Reliability

High-strength Steel

Built with durable, heavy-duty steel for long-lasting performance.

Lip Arc Design

Arched lip structure ensures smoother vehicle transition and reduces impact damage.

Anti-slip Pattern

Surface features a non-slip tread design to ensure safety during operation.

Tonnage Optional

Available in multiple load capacities (6T, 8T, 10T) to meet diverse operational needs.

Imported Brand Motor

Equipped with a reliable, high-performance motor from internationally recognized brands.

Various Types

Offers standard, telescopic, and customized dock levelers for different applications.

Submit Your Custom Requirements

More Details Of Dock Leveler Show!

① Tail lip

② Side curtain safety baffle

③ Lip plate cylinder

④ Platform support steel

⑤ Lifting cylinder

⑥ Hydraulic pump

⑦ Sealing rubber strip

⑧ Yellow and black warning strips

⑨ Pedestal

⑩ Control unit

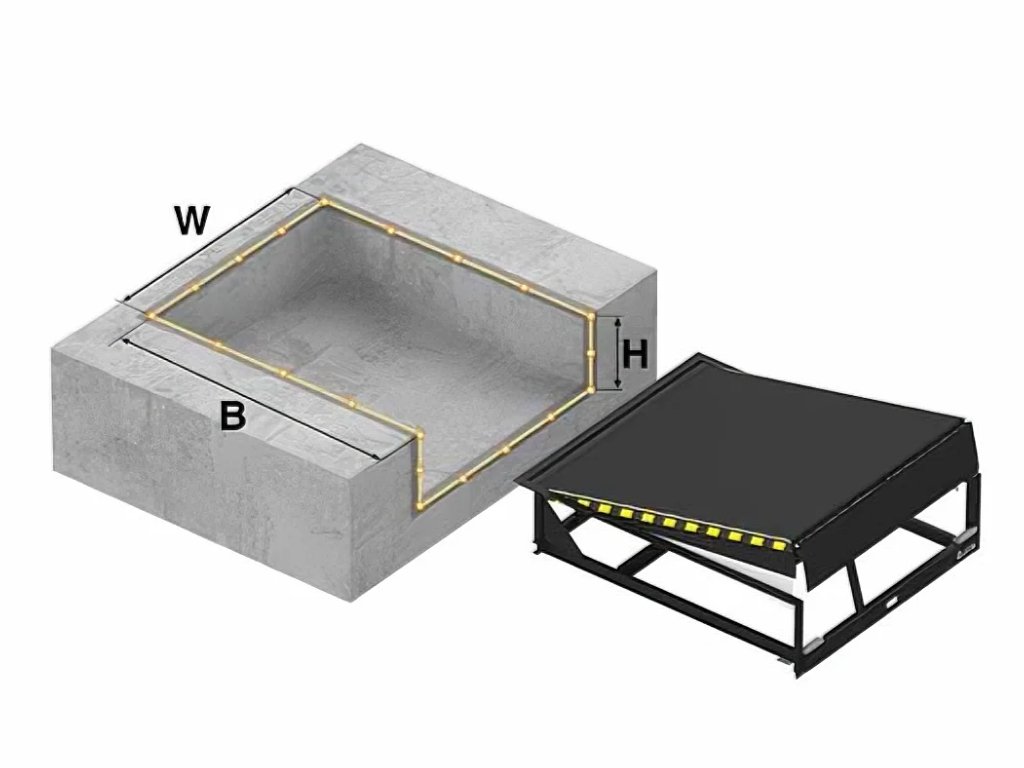

Installation conditions

About the dock leveler, we can design and offer you professional 3D and CAD drawings according to installation conditions. It’s very easy to install a dock leveler when the pit is ready well. It also makes your logistic work more convenient.

Common Types of Dock Levelers

Mechanical Dock Leveler

Mechanical dock levelers are simple, durable, and ideal for moderate traffic. Powered by a spring system and manual pull chain, they reduce costs and require minimal maintenance, making them a cost-effective solution.

Edge of Dock Levelers

Edge of dock levelers are cost-effective and ideal for small loading areas. Mounted on the dock face, they provide safe, ergonomic height adjustment for standard dock heights, making them a popular, budget-friendly choice.

Vertical Dock Leveler

Vertical dock levelers seal tightly when upright, preventing air loss and maintaining energy efficiency. Ideal for logistics, they reduce energy waste and keep the warehouse environment controlled.

Loading Dock Scissor Leveler

Scissor dock levelers provide stable, smooth elevation adjustments for varying truck heights. Hydraulically operated, they offer easy, safe operation, making them ideal for high-traffic environments.

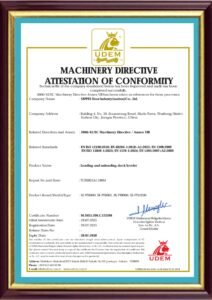

Our Product Certificates

Contact us today to improve your loading operations!

Typical Application Industry Cases

Textle Industry

High-speed doors keep textile workshops clean and climate-controlled, ensuring quality and efficiency.

Logistics Warehouses

High-speed doors improve efficiency and traffic flow in logistics warehouses while reducing energy loss.

AGV linkage

Compatible with AGV systems for efficient logistics flow (AGV not included).

Loading Dock Leveler Demonstration

Here are some selected videos about high-speed doors, covering product demonstrations, installation instructions, and different types of high-speed door applications for your reference:

Our Partners

SEPPES has cooperation customers with more than 70 Fortune 500 companies such as Pepsi, Logitech, Huawei, and Procter & Gamble.

Why Choose SEPPES Dock Plate Leveler ?

Delivering Tailored Loading Solutions for Operational Excellence

Partner to 70+ Fortune 500 Companies

Trusted by 70+ Fortune 500 companies, our quality and reliability meet the highest global standards.

Certified Quality & International Complianc

Certified to CE, SGS, UL, CMA, and ISO standards, we ensure top-tier quality, safety, and reliable performance.

Professional Installation Capabilities

With over 20,000㎡ of advanced facilities and skilled teams, we deliver consistent quality and expert installation for reliable industrial door solutions.

15+ Years of Proven Industry Expertise

With 15+ years of experience, we deliver tailored industrial door solutions backed by deep technical expertise.

Safe Transportation

Once the door is packed, our own dedicated vehicles will be responsible for safely transporting the products to the port for shipment.

Comprehensive Global Insurance Coverage

Your investment is secure with global product liability coverage up to USD 2 million, backed by Ping An Insurance.

Frequently Asked Questions

A dock leveler is a bridge device that safely spans the gap between a loading dock and a truck bed, enabling smooth forklift and pedestrian access.

There are three main types:

1.Mechanical: Spring-powered, manual pull-chain operation.

2.Hydraulic: Electric-hydraulic pump for push-button control.

3.Pneumatic (Air): Air-bag system for environments where hydraulics aren’t ideal.

Consider: total load weight, daily use frequency, required lip-plate extension, dock height variance, and needed safety features (e.g., interlocks, seals).

With proper upkeep, most dock levelers last 5–20 years, depending on type and usage intensity.

Industry best practice is a professional inspection every 90 days to check springs, hydraulics, seals, and safety devices.

Calculate as: (Forklift weight + max cargo weight) × 2.55.

E.g., a 12,000 lb forklift + 3,500 lb load → 15,500 lb × 2.55 ≈ 39,525 lb capacity.

Common causes: weak spring tension, damaged spring assists, or hydraulic/pneumatic faults. Schedule a service call for spring adjustment or system repair.

Often due to aging or improperly adjusted springs. Check and reset spring tension; replace springs if worn.